Client: City of Houston

Location: Houston, TX

The Northeast Transmission Line (NETL) was a project designed to enhance Houston’s water infrastructure. Spanning 16.5 miles with a diameter of up to 108 and 120 inches, the NETL is Houston’s largest water line and aims to augment the city’s water supply by 96 million gallons per day and an additional 269 MGD for the regional water authorities. Aurora played a pivotal role in several segments of the NETL, ensuring the efficient transmission of water from the expanded City’s Northeast Water Purification Plant. Comprising 13 distinct segments, the NETL is a phased project. Aurora was the lead engineer on two segments and provided technical design support on four other segments. The project’s complexity was heightened by its urban setting, demanding meticulous planning, coordination, and innovative engineering solutions. Aurora’s involvement was instrumental in addressing challenges such as the proximity to an existing 84-inch waterline and other infrastructure, major freeways and bayou crossings, and the need for performing interconnections between the 108-inch and existing 84-inch while keeping the 84-inch in service under full operating pressures. Aurora’s team expertise addressed other challenges such as HVTL towers, railroads, and multiple pipeline crossings.

Services Provided:

Lead Engineer: Performed as the lead engineer for two segments meeting project schedules and budgets.

Utility & Infrastructure Coordination: Coordinated with utility owners, stakeholders, and agencies, performed alternative route evaluations to mitigate impacts to existing bridge structures, and managed crossings of major infrastructures such as IH-45 and BW-8.

Design, Risk Assessment & Mitigation: Designed interconnect and related piping details, geotechnical report analysis, and constructability reviews. Identified and mitigated potential risks, developed details, and technical specifications which were used on multiple segments by the City in areas adjacent to the parallel 84-inch waterline.

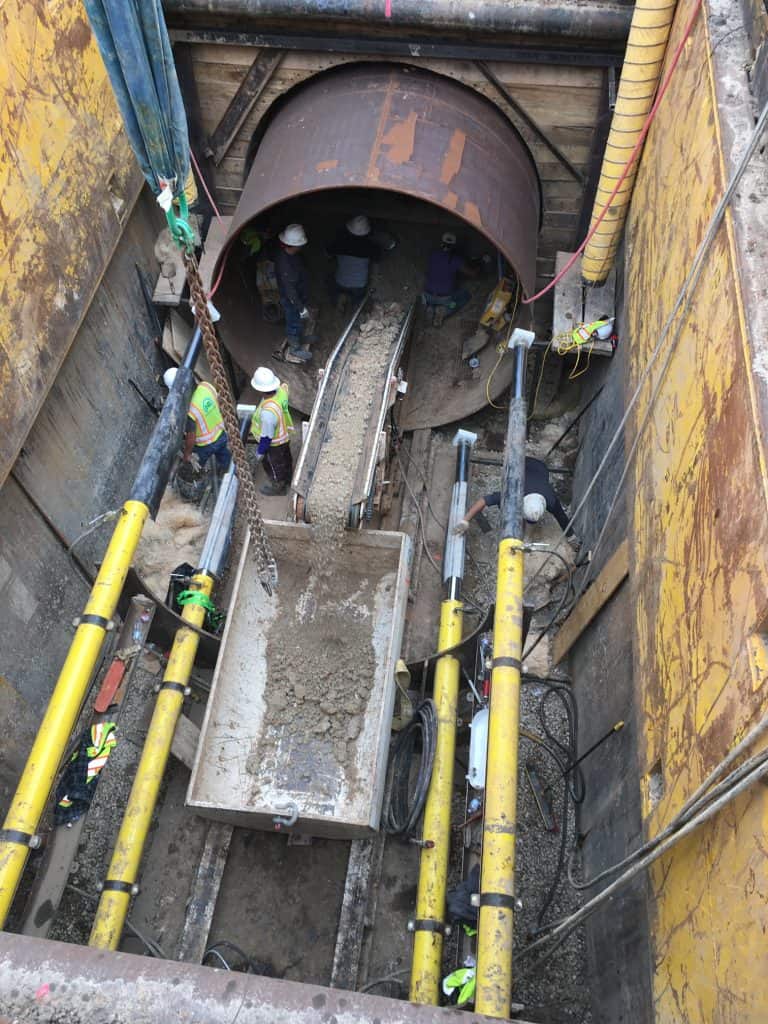

Compact Designs & Proximity Challenges: Developed compact 108-inch diameter fitting designs, devised strategies for working near high voltage towers and monopoles, and addressed the challenge of threading tunneling between existing pipelines to limit pipeline movement.

Pipeline & Bayou Crossings: Determined configurations for multiple pipeline crossings and requirements of bayou drainage ditch crossings that could not be dewatered.

Construction Management Services: Supported the Program Construction Manager to verify contractor adherence to design plans, responded to RFIs, reviewed tunnel work plans and monitoring reports, and provided technical support to RFIs due to field conditions.